Flint Group Narrow Web has invested heavily in two centres where we offer testing and training resources to customers and co-suppliers on a global level. Our two CTEs (Centres for Technical Excellence) are located in Trelleborg, Sweden and Minnesota, USA.

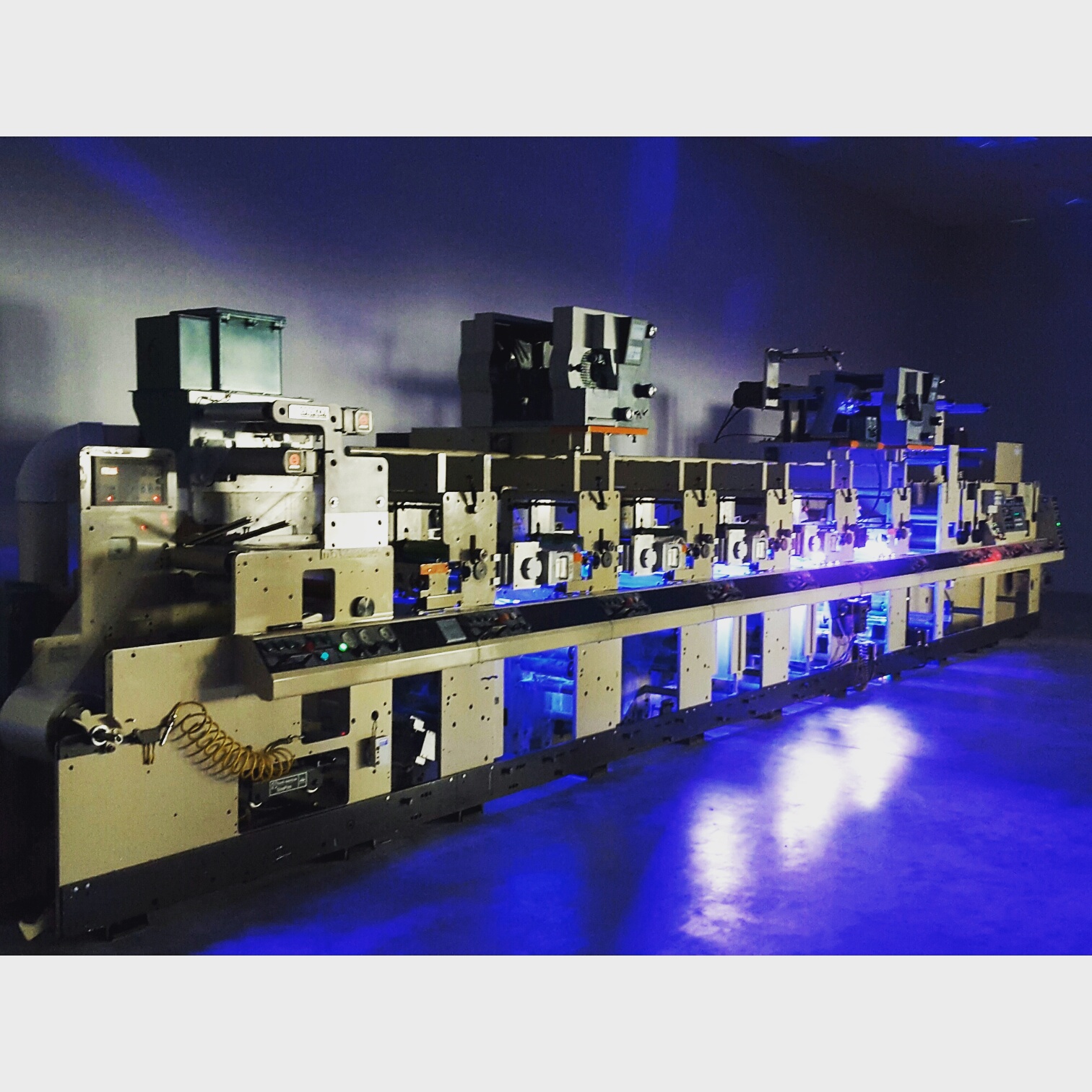

Both CTEs are equipped with fully operational, state-of-the-art printing presses, combining various printing techniques and granting the ability to perform advanced testing of both inks and processes and reproduce real-life conditions.

The CTEs provide unique tools that enable us to work closely with suppliers in these fields, to continuously develop and design solutions that not only live up to the unique demands of today, but also drive the next generation of applications and to create entirely new business opportunities for our customers.

The CTE provides an opportunity to:

- Run tests on state-of-the-art Narrow Web presses

- Test new applications - without the need of capital expenditure

- Troubleshoot existing processes (saving you time and money)

- Participate in all levels of training with our free seminars

For more information about what we can offer at each CTE, please click below on the respective region.